The Cottage City Oyster Farming Process

It's farming, not fishing. So it all starts with...

The Seed

Oyster seed is created in a hatchery. Each Spring, the seed (1mm in size) is shipped to our farm and promptly placed into a grow-out nursery in the Lagoon Pond. The large salt pond provides our baby oysters with enough food, protection and wave attenuation for their first year of growth. Over the first year of growth, our unique nursery system creates a blemish free, wave sculpted oyster about 1” in size. The oysters are then transferred out to our open ocean farm site where they will grow over the next 2.5 years.

Unlike most oyster farms in New England, Cottage City Oysters are grown in deep, cold water and remain submerged underwater for 99% of their lives. This allows the oysters to feed 24 hours a day, unlike farms whose oysters are expose to the air during a low tide. This air exposure causes the oysters to hold their breath until the next high tide comes in. Cottage City Oyster's don't experience this stress, and it's all because of...

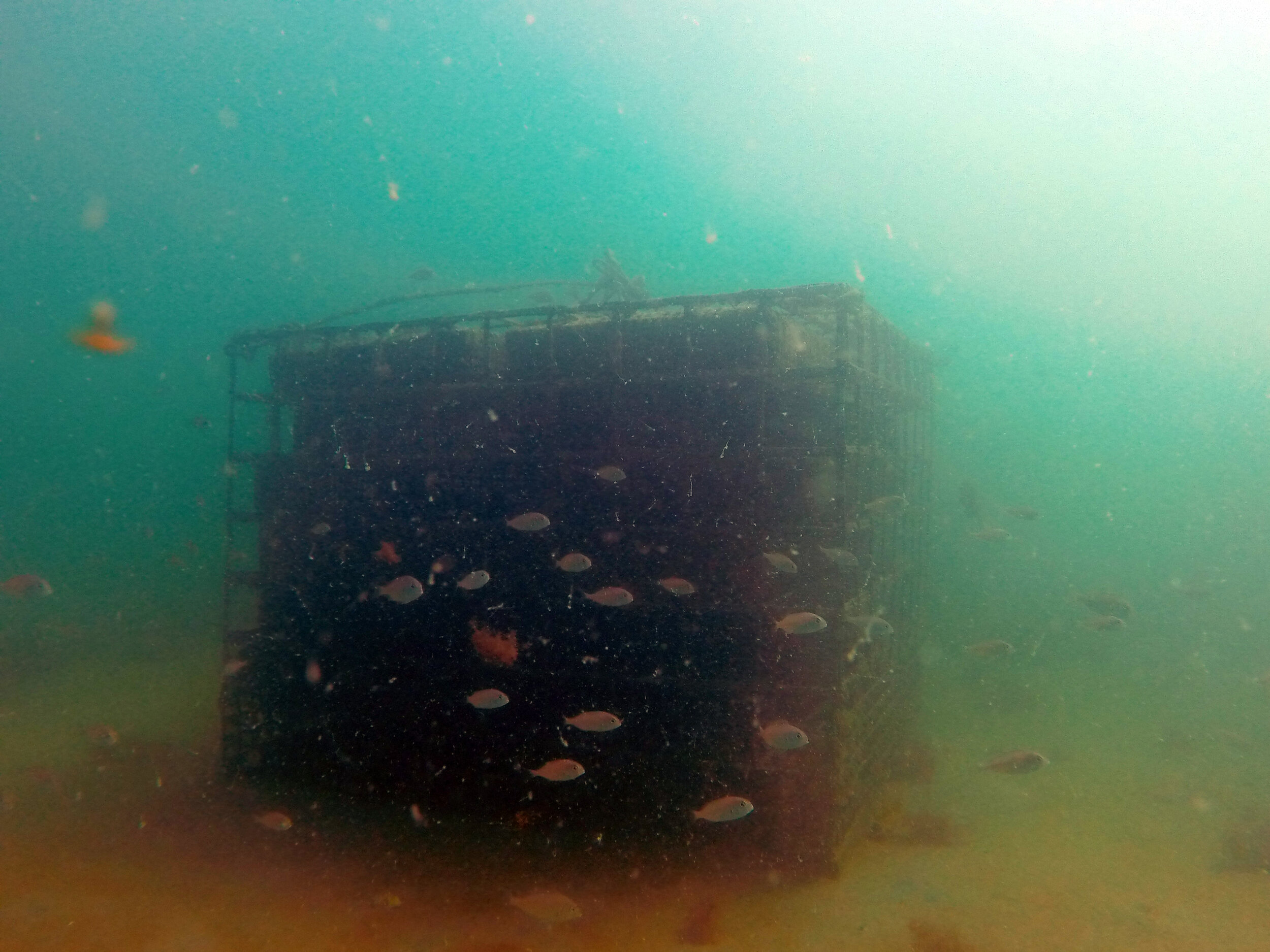

The Cages

Unique to deep water sites, our cages are designed to sit securely on the ocean bottom, protecting the oysters from natural predators and silt and sediment in the meats, all while still maintaining a good amount of water flow. Cottage City Oysters benefit from the clean, swift moving waters of the Vineyard Sound as this powerful water-flow ensures a steady supply of clean food while deterring disease which can breed in stagnant pond water. The cages are brought to the surface and cleaned while the oysters are graded by size and restocked into their fresh cages. This cleaning process happens a couple times a year and wouldn't be possible without...

The Raft

Our home away from home. Built entirely from eco-friendly green products, the raft is where we spend the majority of our days. All of the raft's equipment runs off of electricity that are powered by two solar power panels mounted to the work table. During the cleaning cycle, we grade the oysters for size and shape, making sure to keep uniform size oysters together in the grow cages. Each oyster is handled more than 100 times on the farm and finally reaches a market size after about 3.5 years. Once they reach this age we begin...

Culling

Cottage City Oysters are crafted the old fashion way, by hand. Each oyster is hand sculpted throughout it’s 3 years of growth on the farm, to create a perfect tear drop shape with a deep cup. Air drying and a regimented cleaning program over those 3 years aims to deliver a product with blemish free outside, and a pearly white inside. Oysters grow at different speeds, and we make sure that uniformity is our middle name. We take pride in selecting only the oysters which have these highest attributes, which is why Cottage City Oysters can be trusted by world renown chefs time and time again. Over the 3.5 years on the farm, it takes hundreds of hours to develop these key attributes, and culling is when we get to see the fruits of our labor.

The Market

Our commitment to perfection does not stop on the farm. After the oysters have been culled and clean, we promptly sell the oysters to the market. In fact, we will not pull our oysters from the water unless we know they are being sold that same day. This ensures the freshest product possible, straight from the water to your table. It takes a lot to get them there, but we know you enjoy it as much as we do.